RTE/RTS FOOD PLANT / MACHINES FOR RTE/RTS LINE

RTE / RTS Food Processing Plant

by

B SEN BARRY & CO.

“Precision in Processing” — From Regional Recipes to Global-Ready Packs.

🏭

Plant Overview

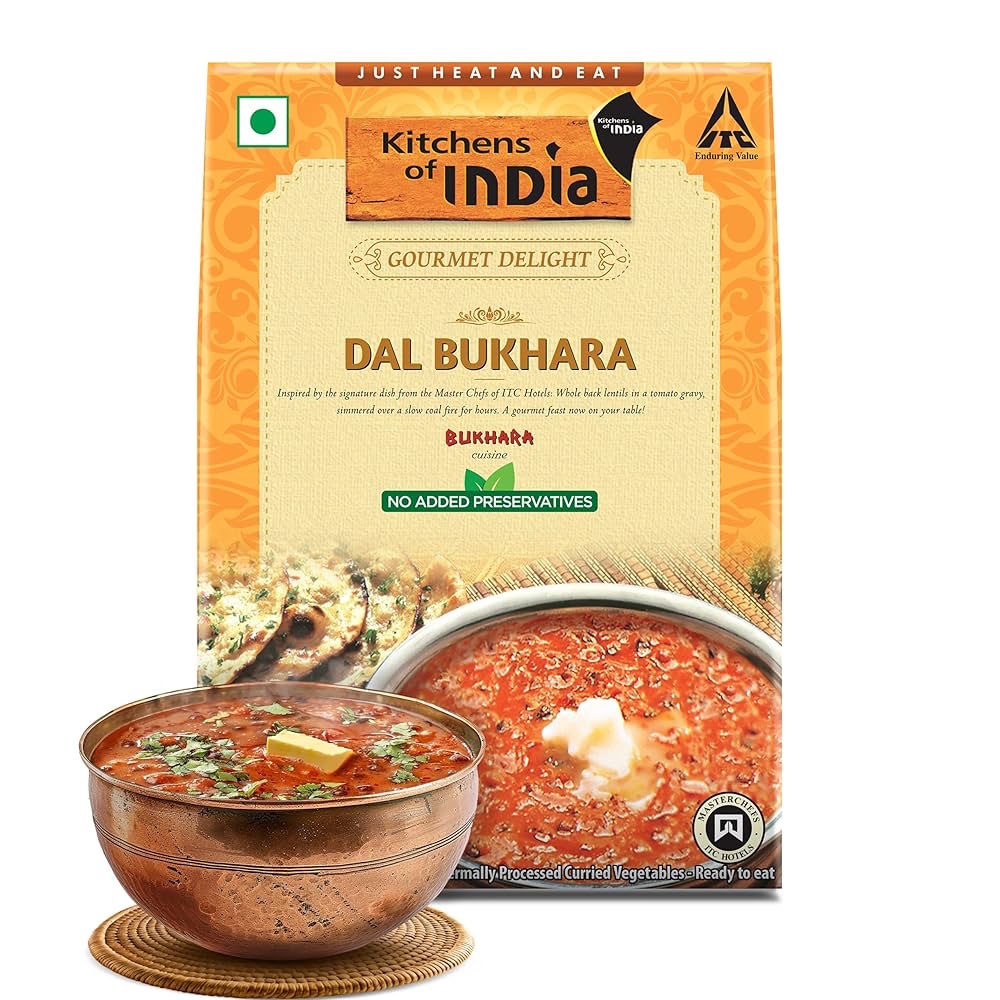

The RTE (Ready-to-Eat) and RTS (Ready-to-Serve) segment is India’s fastest-growing food category — driven by urban demand, exports, military supplies, and instant meal kits.

At B SEN BARRY & CO., we design fully integrated RTE/RTS plants to process and package a wide range of cooked Indian meals, gravies, curries, dals, biryanis, rice mixes, khichdi, and beverages, ensuring safe, shelf-stable products without refrigeration.

🍛

Product Examples

✅ Ready-to-Eat (RTE)

Rajma chawal, dal makhani, sambar rice, khichdi, veg pulao

Paneer butter masala, chicken curry, aloo gobhi, chana masala

Halwa, upma, poha, biryani

✅ Ready-to-Serve (RTS)

Aam panna, jal jeera, buttermilk, lassi

Tomato soup, rasam, flavored milk

Coconut water, tender coconut beverage

🛠️

Core Equipment in the RTE/RTS Line

1.

Raw Material Washing & Preparation

Bubble washer, vegetable cutter, slicer, fruit peeler, ginger/garlic paste grinder

2.

Cooking & Blending System

Steam-jacketed kettles with anchor stirrers for curries, dals, gravies

Batch or continuous cookers for rice, pasta, upma, biryani

Optional vacuum cooking or pressure cooking for delicate recipes

3.

Holding & Buffer Tanks

Insulated or jacketed with gentle agitator

Equipped with level sensors and CIP nozzles

4.

Filling Machines

Pouch filler, retort pouch filler, bottle/jar filler, or tray filler

Servo/piston-based for hot or ambient filling

Volumetric or weight-based control

5.

Sealing & Capping

Automatic pouch sealers, tray sealers, jar cappers, or retort spout pouch sealers

Leak-proof design with tamper evidence

6.

Retort / Autoclave

For RTE meals: High-pressure sterilization

Ensures 12–18 months shelf life without preservatives

7.

Pasteurizer / Hot Water Tunnel

For RTS beverages: Gentle thermal pasteurization

Preserves natural color and flavor

8.

Cooling & Drying

SS cooling tank or conveyor

Air knife or blower dryer before labeling

9.

Labelling & Secondary Packing

Shrink sleeve or sticker labelling

Batch coding, carton packing or shrink bundling

⚙️

Plant Capacity Options

Pilot Scale: 200–500 kg/day

Mid-Capacity: 1–2 MT/day

Industrial Scale: 3–10 MT/day

📦

Packaging Formats Supported

Retort Pouches (3-layer or 4-layer)

Glass Jars / Bottles

PP Trays with Heat Seal

Stand-up Spout Pouches

Aseptic Pouch (optional)

🌟

Why B SEN BARRY & CO.?

Machines trusted by 10,000+ food units and exporters

Built to FSSAI, GMP, and global export standards

Stainless steel SS 304/316 build, CIP-compatible

Designed for minimal labor, maximum automation, and recipe integrity

Supporting India’s rise in the global RTE/RTS market