MANGO JUICE PLANT / MANGO PROCESSING PLANT / MANGO PULP CANNING MACHINES / MANGO JUICE MAKING UNIT

Mango Processing & Juice Plant

by

B SEN BARRY & CO.

“Precision in Processing” — Turning the King of Fruits into Global-Grade Products.

🏭

Overview

India is the largest producer of mangoes, but true value lies in processing it into juices, purées, concentrates, nectar, pulp, and beverages. At B SEN BARRY & CO., we provide turnkey mango processing lines designed for seasonal speed, export-grade hygiene, and maximum recovery of yield and aroma.

🍹

Final Products You Can Make

Mango Juice (RTS) – ready-to-serve bottled or pouched juice

Mango Pulp / Purée – for domestic and export use (9–12° Brix)

Mango Concentrate – 28° Brix or above for beverage manufacturers

Mango Nectar, Aam Panna, Aam Ras

Flavored Mango Drinks (with/without carbonation)

⚙️

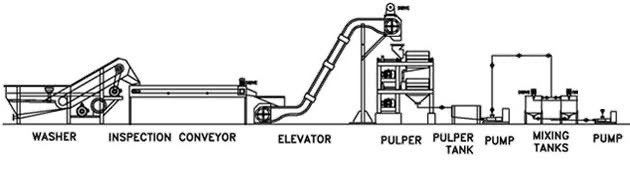

Key Machines in the Mango Processing Line

1.

Mango Washer

Bubble washer or rotary washer to clean surface impurities

Optional brushing system for skin residue removal

2.

Sorting Conveyor

Manual inspection of raw fruit on SS table with chute for waste

3.

Destoner / Pulper

Mango destoner with scraper-type pulping

Separates seeds and fibers from pulp

Available in single or double-stage for higher yield

4.

Deaerator (Optional)

Removes air from pulp to prevent oxidation and preserve color

5.

Evaporator (for Concentrate Production)

Open-pan or vacuum evaporator

Converts pulp into 28° Brix concentrate

Preserves natural color and flavor

6.

Pasteurizer

Plate or tubular heat exchanger

Kills microbial load without degrading quality

7.

Homogenizer (for Juices)

Ensures smooth mouthfeel and stable product suspension

8.

Filling Machines

Hot-fill or cold-fill systems

Options: Bottles, tetra packs, cans, pouches, or drums

Servo-based piston or volumetric fillers

9.

Retort (For Pouches/Tins) or Cooling Tunnel

For shelf-stable packaging with or without preservatives

Suitable for export-compliant long shelf life

10.

Labeling & Packing

Shrink sleeve, sticker labeling

Inkjet batch coding and carton packing systems

🧴

Packaging Formats Supported

200ml to 1L PET bottles

Glass bottles, stand-up pouches

Aseptic bags (for bulk)

5kg/20kg/200kg drums for pulp export

Tins or cans (850g / 3.1kg)

🔩

Plant Capacities

Small Scale: 500 kg/hr

Mid Scale: 1–2 TPH

Industrial Scale: 3–10 TPH+

🌟

Why B SEN BARRY & CO.?

4 generations of food machinery expertise

Over 10,000+ installations across India and Africa

Machines engineered for seasonal rush, minimum waste, and long-term durability

SS304/316 build, CIP-compatible, FSSAI/export compliant

Supporting India’s mango clusters in UP, Maharashtra, South India, and Bihar