ORANGE JUICE PRODUCTION AND FILLING LINE

Orange Juice Production & Filling Line

by

B SEN BARRY & CO.

“Precision in Processing” — Capturing Freshness, Bottling Purity.

🏭

Overview

India is emerging as a major player in citrus juice processing, especially from regions like Nagpur, Coorg, and Punjab. Whether for domestic brands or export markets, orange juice requires a clean, efficient, and hygienic setup to preserve vitamin C, natural aroma, and shelf stability.

At B SEN BARRY & CO., we offer turnkey solutions for fresh orange juice, juice with pulp, concentrate, and blended citrus beverages, from fruit reception to final packing.

🧃

End Products You Can Manufacture

100% Fresh Orange Juice (Not From Concentrate – NFC)

Reconstituted Juice (from concentrate)

Juice with pulp

Orange-based RTS drinks or blends

Aseptic or hot-fill juice bottles

Concentrate for export (Brix 60–70°)

⚙️

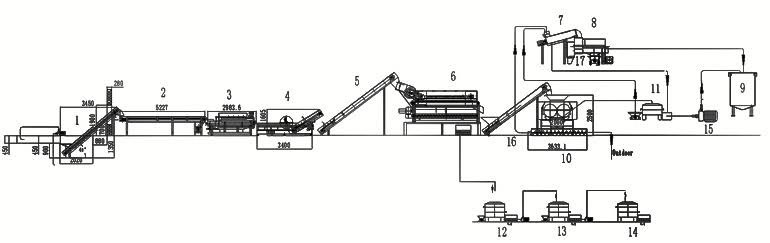

Key Machinery in the Line

1.

Fruit Washer

Bubble washer or rotary washer with brushes

SS304 tank, food-grade materials

2.

Fruit Grading / Sorting Line

Manual or automatic sorting

Removes damaged, unripe, or moldy fruit

3.

Citrus Juice Extractor

Twin-head juice extractor with in-built peeling

Extracts juice while separating seeds and rind oils

Retains juice clarity and taste

4.

Pulp Separator / Finisher (Optional)

Adjust pulp content as per final product

Fitted with SS mesh of various grades

5.

Deaerator

Removes oxygen to prevent oxidation and vitamin loss

Increases shelf stability

6.

Pasteurizer

Tubular or plate heat exchanger

Flash pasteurization between 85–95°C

Retains nutrients while ensuring microbial safety

7.

Homogenizer (Optional for blends)

For smooth texture, uniform mixing in pulp-added juices

8.

Holding Tank

Jacketed or insulated SS304 tank

With level controller, agitator, and CIP-ready port

9.

Filling Machine

Hot Fill or Cold Fill options

Types:

Servo-based Piston Filler (for pulpy juices)

Gravity or Vacuum Filler (for clear juice)

Rotary Bottle Filler (for high-speed lines)

10.

Cap Sealer

ROPP, screw cap, or lug-type cap depending on bottle

Fully automatic with torque control

11.

Cooling Tunnel

Reduces filled juice temperature rapidly

Prevents microbial growth and shrinkage

12.

Labelling & Batch Coding

Shrink sleeve or self-adhesive labels

Inkjet coding for date, batch, MRP

Carton taping or shrink wrapping unit

📦

Supported Packaging

PET bottles (200 ml – 2 L)

Glass bottles

Spout pouches or stand-up pouches

Aseptic bags or drums (for concentrate)

🔩

Plant Capacity Options

Starter Line: 500 liters/hr

Standard Line: 1000–3000 liters/hr

Industrial Line: 5–10 TPH and above

🌍

Why B SEN BARRY & CO.?

4 generations of processing expertise

Citrus lines installed in India, Africa, Middle East

Machines built to FSSAI, ISO, and export norms

SS 304/316 build, energy-efficient, CIP-friendly

Helping India process its surplus citrus into value-added beverages